—— COMPANY PROFILE

BOTIN SMART TECHNOLOGY(GUANGDONG) CO., LTD.

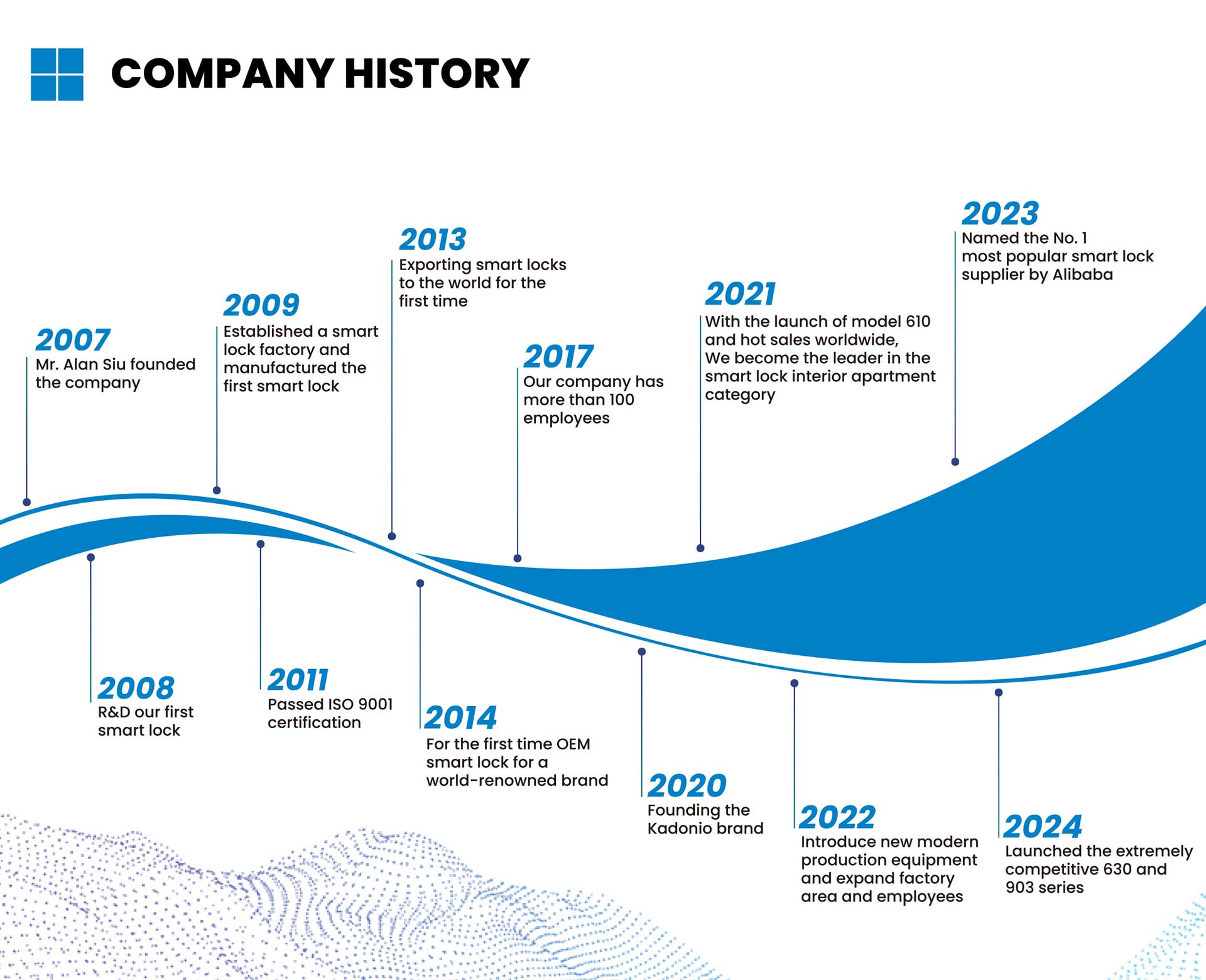

Botin Smart Technology (Guangdong) Co., LTD., a leading smart lock manufacturer based in Shantou, Guangdong, China, was founded in 2007. We specialize in advanced R&D, precision manufacturing, and quality assurance, delivering reliable and cost-effective smart lock solutions.

With a team of over 100 professionals and a registered capital of 20 million RMB. Our commitment to top-tier quality is validated by international certifications, such as CE, FCC, ROHS, and ISO 9001. Furthermore, our collection of smart lock patents showcases our innovative edge and unwavering emphasis on product safety.

Throughout our impressive 18-year trajectory, we've pioneered more than 100 smart lock variants. Our zeal for innovation propels us to launch at least 10 groundbreaking products every year. With a presence spanning 70 countries and the trust of over 1,000 partners.

Kadonio is a brand of Smart Home Appliances. Introduced by BOTIN(ASIA) LIMITED.

We focus on SMART HOME PRODUCTS such as wifi smart locks, bluetooth smart locks, video doorbell locks smart cabinet locks, smart curtains and so on, to make life more simple and secure.

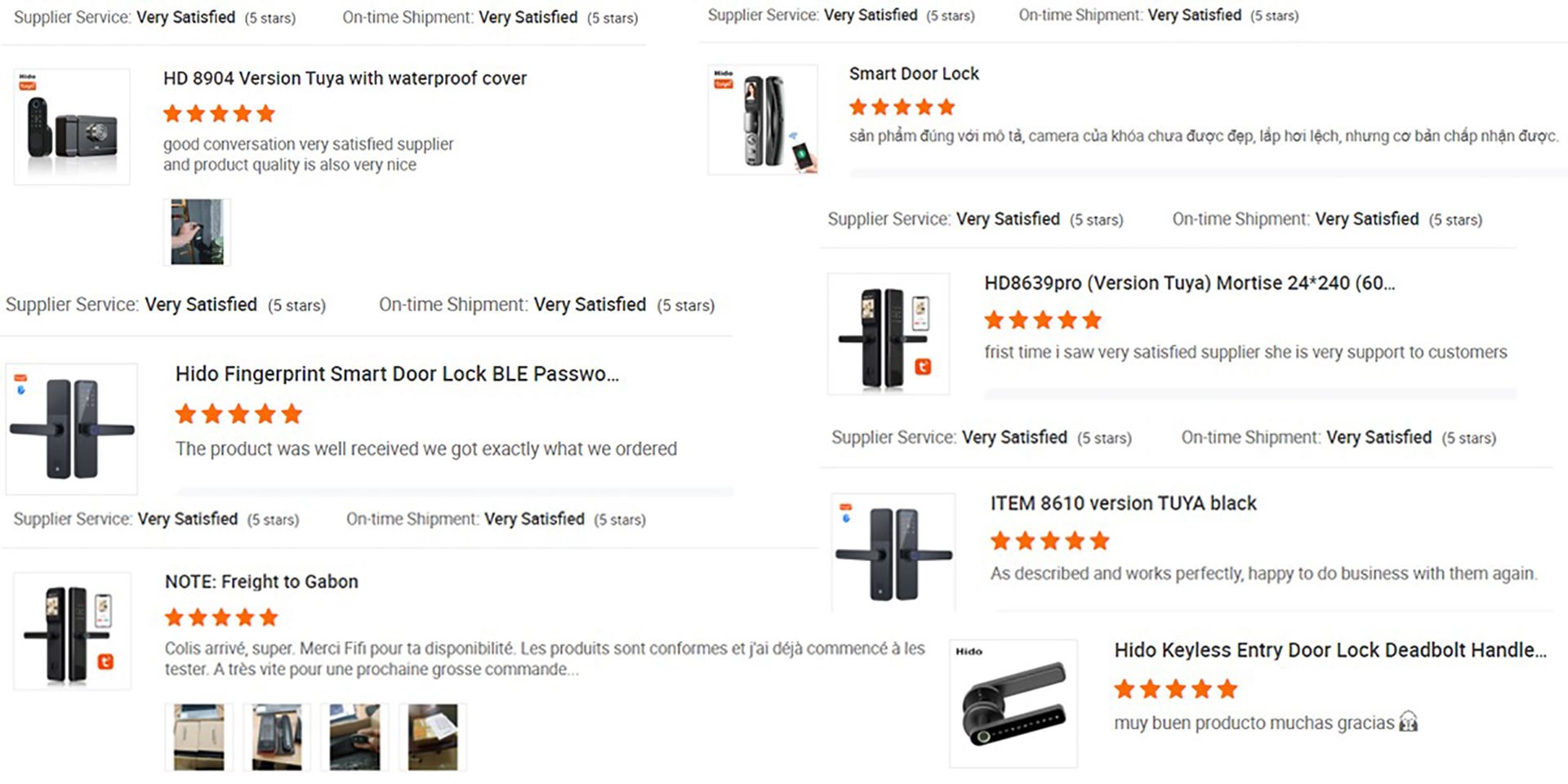

Our product got quality certified by TUV. “Quality first, Customer first" is our company’s tenet. Adhering to business principle, Our QC follow up each step closely, to ensure that every product can meet the customers’requirements. And we earn good reputation among all of our customers.

We provide OEM and ODM one-stop service. Warmly welcome to discuss the desiqn with us. Looking forward to working with our current and new partners toward a promising future.

Quality Control Process

1. R&D period

All of our new products have established perfect testing standards in the early stage of research and development. In the prototype stage, the engineering prototype stage will require passing various tests. Finally, the new product is allowed to enter the batch trial production stage after the review is completed. All questions are required to complete the closed loop before trial production;

2. Full inspection period of raw materials

key raw materials. Such as clutch, micro switch, PCB, fingerprint module, etc., we implement 100% full inspection;

3. Assembly period

The production management provides professional training for front-line assembly staff, and assembles in strict accordance with the operation instructions;

4. Full inspector inspection

Each production line in the production workshop is equipped with a full inspector position, and is required to conduct inspections in strict accordance with the inspection

instructions;

5. Acceptance and sampling period

Before shipment, the quality department conducts sampling inspection on the finished products according to the ISO2859 standard, and all kinds of products have perfect acceptance standards;

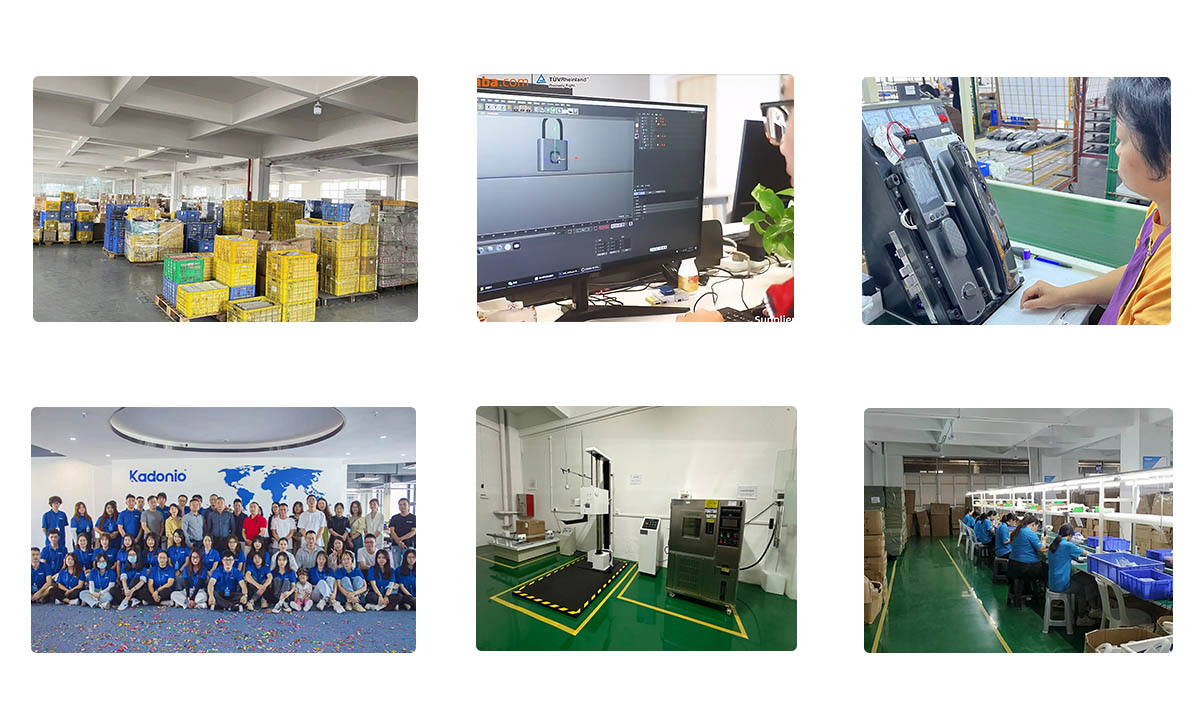

Our Factory

Our factory covering 2400 square meters. Production dept. have 50-60 workers to realize fast shipping. 5 in-line QC to process quality control strictly.

Our tenets are "Customer first" and "High-quality, low price." We always try to pursue good quality and inexpensive products to bring our customers more satisfaction and value in life.

Our advantages include competitive prices, excellent quality and 24-hour service, and Support for OEM, ODM, Drop Shiping. We provide a complete set of solutions to help you from purchasing products to selling products. For instance, we can provide you with HD photos, videos, details page, and we can help you search for the most popular products and the latest trends in the local market with big data and so on to help you sell the products.

We can provide free samples once a year for customers who place a second order, and we will give a surprise discount from time to time if you become our fans. We look forward to working with you to become a long-term partner!